At the end of their 20-to-30-year lifespan wind turbines have to be removed and recycled. Disposing of wind turbines – sustainably and with a low impact on the environment.

Recycling of wind turbines

Recovery, disposal and recycling of wind turbines and rotor blades.

01

EURECUM uses an industrial excavator with a diamond cutting wheel of the model KEMROC KDS 50 to break down the rotor blades of the wind turbines.

02

After the preliminary crushing process the individual elements are cut into smaller, more manageable pieces using the hydraulically driven cutting wheel.

03

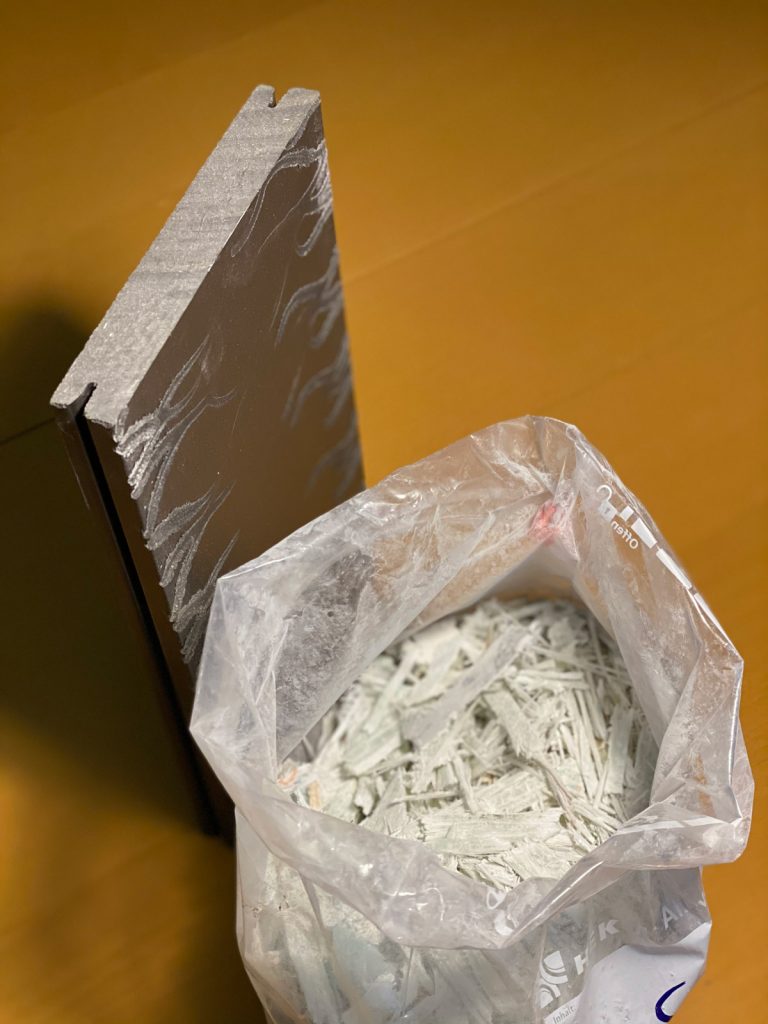

The process developed and used by EURECUM has proven itself many times in practice. These parts which are made of GFK material are ready for the automated secondary crushing process.

04

Following further processing steps, we end up with a fine-grained granulated finished product which can serve as a high-quality recycled raw material.

In the coming years thousands of wind turbines will have to be dismantled and as far as possible be replaced by new ones. The recycling company EURECUM has developed a conclusive process for the preliminary and secondary crushing of rotor blades. The residual material can be used either as an alternative source of fuel or re-employed at a high recycling level.

In the next few years all across Germany thousands of wind turbines will be approaching the end of their contractually stipulated lifecycle. According to the registered German Federal Association of Wind Energy this amounts to a total output of 3,800 to 4,000 megawatts as of January 1, increasing up to a total output of around 16,000 megawatts by the end of 2025. Turbines which cannot continue to be run economically will have to be dismantled. Many of the intact first-generation turbines can be re-used in other countries. However, technologically outdated turbines as well as second-generation plants must be disposed of. They are so complexly and technologically built that it does not make economical sense to re-install them somewhere else. When removing the disused turbines many materials are able to be recycled in a technologically easy manner at a high quality.

Concrete taken from the bases and gravel from the substructure can be re-deployed in road construction; Steel and electronic scrap as well as non-ferrous irons can be separated into different grades and also recycled. One of the most pressing concerns in the past was how to minimize and process the gigantic rotor blades, which are predominantly made of GFK (fibreglass reinforced material). The recycling company EURECUM based in Lutherstadt Eisleben in Saxony-Anhalt has developed a disposal process whereby the rotor blades are efficiently cut at the site of the wind turbine and then, after transporting the cut blades to the waste disposal plant, they are crushed to make an industrially viable GFK granulate.

Customized Removal Concepts

Crushing and disposal of foundations, towers, engine pods and rotor blades. Professional and fast dismantling into appropriate individual parts.

Rotor Blade Dismantling

In preparation of the recycling process a segmentation procedure is carried out using an enclosed saw during which all segments, dusts and cooling liquids are captured. Following this the valuable copper and aluminium elements found in the rotor blades are recovered. Fibreglass reinforced materials are sometimes added energetically and materially as an alternative fuel.

Recycling

The valuable copper and aluminium elements found in the rotor blades are recovered. Fibreglass reinforced materials are sometimes added energetically and materially as an alternative fuel.

Alle Bilder: KEMROC